Overview

Electromagnet crane for scrap charing in scrap yard and charging scrap into furnace in steel plant

Steel foundry electromagnet crane mainly consists of bridge, crane traveling mechanism, trolley, electric equipment and electromagnetic chuck, and could be classified into several working duties, e.g. A5, A6, A7, according to the working frequency and pure working time

When used, the rotary part of the hanger of electromagnetic disk must be locked up with screws and no rotation is allowed.

The crane mainly relies on the magnet, using the electromagnetic principles, then through electricity and magnetic plate to suck the goods firmly hanging to the designated place.

Cut the electricity, steel and irons will be lay down. It is the most convenient crane to transfer the scattered sheet metal.

Lifting material: cast ingot, steel scraps, steel ball, steel billets.

Wide use in steel plants, melting plant, waste warehouse, billet processing workshop.

Features

High working efficiency, safe and reliable operation. Perfect performance, Low maintenance.

1. MW5 Series magnet to lift steel scraps,round type,dia.from 700 to 2400mm.

2. MW61 Series magnet to lift steel scraps,elliptic type,length from 1400 to 3000mm.

3. MW12 Series magnet to lift bundled steel bar,square type,length from 1100 to 1800mm.

4. MW22 Series magnet to lift steel ingot, square type,length from 800 to 2500mm.

5. MW42 Series magnet to lift steel billet and profile steel.

6. Temperature of lifting material is below 100'C,pls choose normal type.

7. Temperature of lifting material is below 100'C,pls choose high temperature type.

8. When power-on sustaining rate is above 60%,pls choose high frequency type.

9. When lifting and transporting material in water,pls choose diving type(depth of diving 100m),the technical data of diving type electromagnet is same as that of normal temperature type,when ordering,pls pls state clearly the details.

Specification

QC Model Electromagnetic EOT Crane | |||||||||||

Lifting Capacity | T | 5t | 10t | 16t | |||||||

Working Duty | A6 | ||||||||||

Span | m | 7.5~31.5m | |||||||||

Max. Lifting Height | m | 16 | 16 | 16 | |||||||

Electromagnetic disk | Type | MW1-6 | MW1-16 | MW1-16 | MW1-16 | ||||||

Suck weight | kg | 4540 | 3330 | 8330 | 14330 | ||||||

Dead weight | 460 | 1670 | 1670 | 1670 | |||||||

Diameter | mm | 776 | 1180 | 1180 | 1180 | ||||||

Lifting Capacity | T | 16/3.2 | 20/5 | 32/5 | |||||||

Electromagnetic disk | Type | MW5-165L6 | MW5-180L | MW5-210L | |||||||

Suck weight | kg | 12500 | 14500 | 21000 | |||||||

Dead weight | 3200 | 4230 | 7000 | ||||||||

Diameter | mm | 1650 | 1800 | 21000 | |||||||

Lifting Capacity | T | 50/10 | |||||||||

Electromagnetic disk | Type | MW5-90L | |||||||||

Suck weight | kg | 4200 | |||||||||

Dead weight | 800 | ||||||||||

Diameter | mm | 900 | |||||||||

Steel track recommended | QU70 | ||||||||||

Power Supply | By your country 3phs voltage | ||||||||||

CASE

Explore how our magnetic overhead cranes are applied in real-world industries. From scrap yards to steel production lines, our project cases showcase reliable, efficient lifting solutions tailored to diverse operational needs. Discover more crane systems designed for your industry.

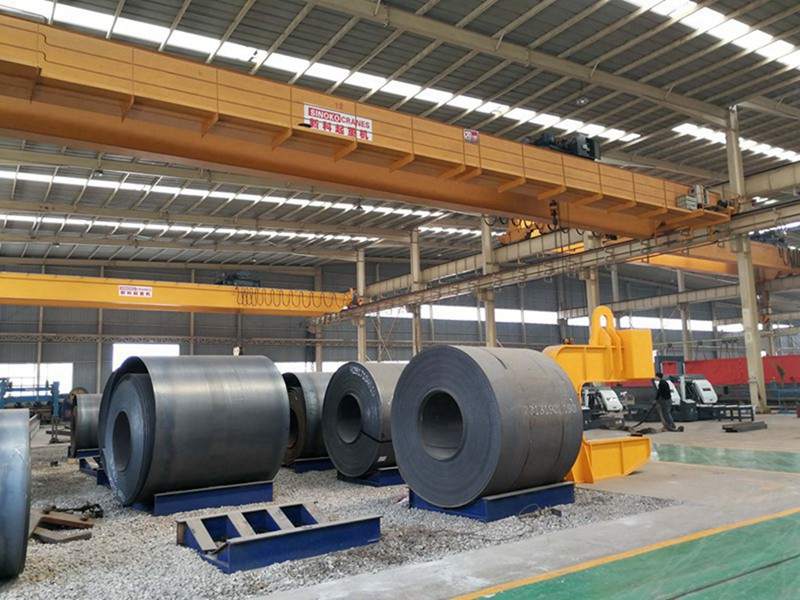

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a QuoteAutomotive Repair Facility in Russia 5 Ton Workshop Bridge Crane Project Case

The Sinoko crane, a 5-ton bridge crane tailor-made for a Russian customer's auto repair shop, has helped the customer solve the problem of lifting and transportation, improved the customer's work efficiency, and saved the customer's work costs.

Learn More Get a QuoteFAQs

This crane is prominently used for scrap charging—transferring steel scraps into furnaces—in steel mills, foundries, and waste warehouses. It leverages an electromagnetic disk to lift ferromagnetic materials like cast ingots, billets, and steel scraps efficiently and safely.

The QC model offers a 16 t lifting capacity, operates under A6 duty class, spans between 7.5 m and 31.5 m, and achieves a maximum lifting height of 16 m.

Multiple options are offered: round (MW5 series), elliptical (MW61), square (MW12 for bundled bars, MW22 for ingots), and billet/profile‑specific (MW42), tailored to various scrap shapes and sizes.

It handles a range of ferrous materials—including cast ingots, steel scraps, steel balls, and billets—making it versatile for diverse scrap-handling operations.

Designed for continuous, heavy-duty performance, this crane aligns with working duty class A6, suitable for high-frequency industrial cycles.

Combining high operational efficiency with reliable performance, it offers simple maintenance, strong structural integrity, and a magnet system built for safe operation and long-term durability.