Overview:

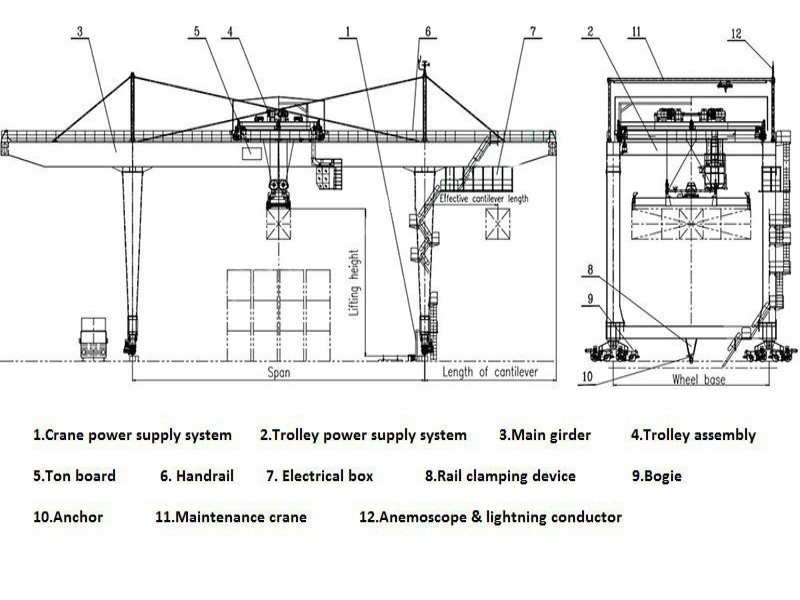

RMG container cranes is constituted by main girder, rigid and flexible outriggers, trolley travel mechanism, lifting mechanism, crane travel mechanism, electric system and operation cab.

RMG Container Crane Specification:

1. Capacity:5-50ton

2. Span: up to 40m or as required

3. Working duty: A5/A6

4. Voltage supply: 220-440V, 50/60Hz, according to local conditions.

Features

I. RMG Container Crane Structure:

Double welding box girder, DIN/FEM standard deflection, Steel tube legs. It runs on a runway at the floor level. The bridge is supported by a pair of rigid steel legs which are carried by a pair of end trucks along the floor level runway.

II. RMG Container Crane Manufacturing Details:

Whole length CNC cutting for complete web plate, high deflection accuracy

High quality automatic welding and NDT inspection. Shot-blasting Sa2.5 for complete girder after welding, stress release. Epoxy zinc rich high quality painting, 2x2 with 140μm

10.9 class High tension bolts mounting between girder and legs, life time safety connection

Vertical gear motor driving, more safety and smaller space

High protection class IP55, F class, 40% ED

III. RMG Container Crane Power supply cable and control cable along the girder

A protective earth conductor is fitted as standard, a crane switch is provided.

Travel end switches, long and cross travel limited y means of preliminary and final limited switches and overload protection.

IV. RMG Container Crane Cabin Operation Control

Two steps push button or joy stick station with emergency stop

Professional chairs, adjustable and fully turning

Easy operation

Round window, big view

End carriage equipped with anti-friction bearings, cellular buffers, derailment protectors.

Specification

Following technical specification is for reference. Spreader is for container 20`,40`and45`. | |||||||

Capacity of Spreader | t | 30.5 | 35 | 40.5 | 50 | ||

Working Duty | A6 | A6 | A6 | A6 | |||

Span | m | 35 | 35 | 35 | 35 | ||

Base | m | 16 | 16 | 16 | 16 | ||

Lifting Height | m | 15.4 | 15.4 | 18.2 | 18.2 | ||

Speed | Hoisting | With full load | m/min | 12 | 12 | 18 | 18 |

Only with spreader | 24 | 24 | 36 | 36 | |||

Traverse | 60 | 60 | 70 | 70 | |||

Traveling | 45 | 45 | 45 | 45 | |||

TotalPower | KW | ~200 | ~230 | ~255 | ~300 | ||

Max. Working Load of Wheel | KN | 260 | 260 | 280 | 300 | ||

Crane Rail | P50 | P50 | P50 | QU80 | |||

Power Supply | Three Phases,380V/50HZ or as required | ||||||

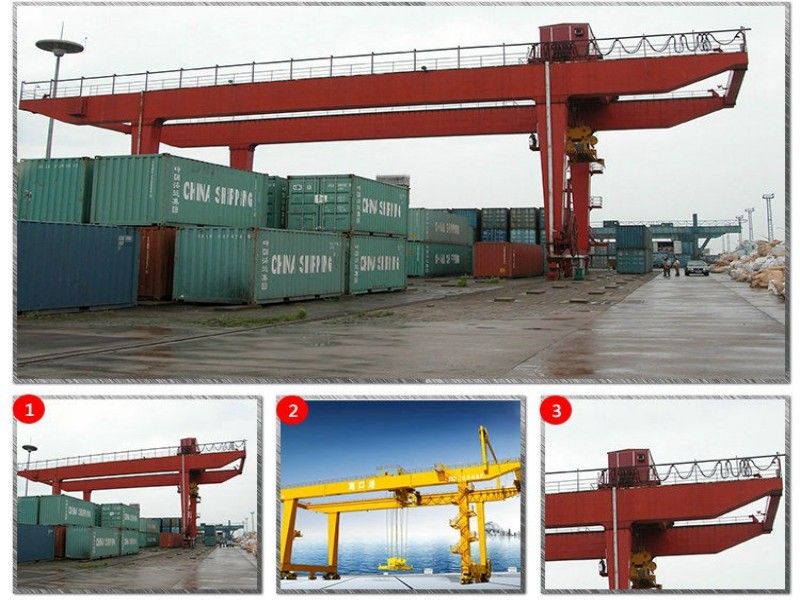

CASE

Explore how the Rail-Mounted Mobile Gantry Container Crane enhances container handling efficiency. With its high mobility and robust design, it offers seamless operation in ports, rail yards, and logistics centers, improving productivity and reducing operational costs.

40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a Quote5T Portable Gantry Crane Deployment for Australian Equipment Rental

The portable gantry cranes provided by Sinoko Cranes for the leasing company of Australian customers have significantly increased the number of rentals for the customers and enhanced the revenue of their companies.

Learn More Get a QuoteInstallation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a QuoteFAQs

The Rail-Mounted Mobile Gantry Container Crane is designed for efficient handling of containers in ports, logistics centers, and rail yards, providing high mobility and precision for lifting heavy containers.

This crane can handle container loads of up to 50 tons or more, depending on the specific configuration, making it ideal for heavy-duty container handling and transportation in industrial settings.

The rail-mounted design provides enhanced stability and smooth movement along fixed tracks, ensuring the crane can safely and efficiently transport heavy containers over long distances within a port or warehouse.

Yes, the crane is customizable in terms of span, lifting height, and drive systems to meet the specific needs of different operational environments, including indoor and outdoor use.

The crane offers high mobility, energy efficiency, reduced operational costs, and enhanced safety features, making it ideal for container handling in busy port environments and rail yards.

Regular maintenance includes checking the mechanical systems, inspecting the rail tracks, and ensuring that electrical components and safety features are functioning correctly for safe and reliable operation.