Overview:

Industrial Double Girder Gantry Crane China Introduction:

1. It is a medium and heavy size crane which travels in track.

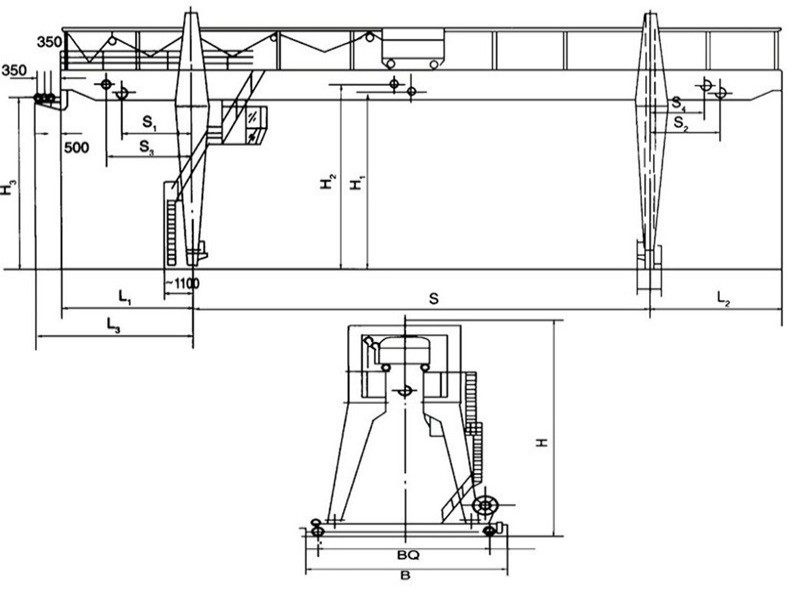

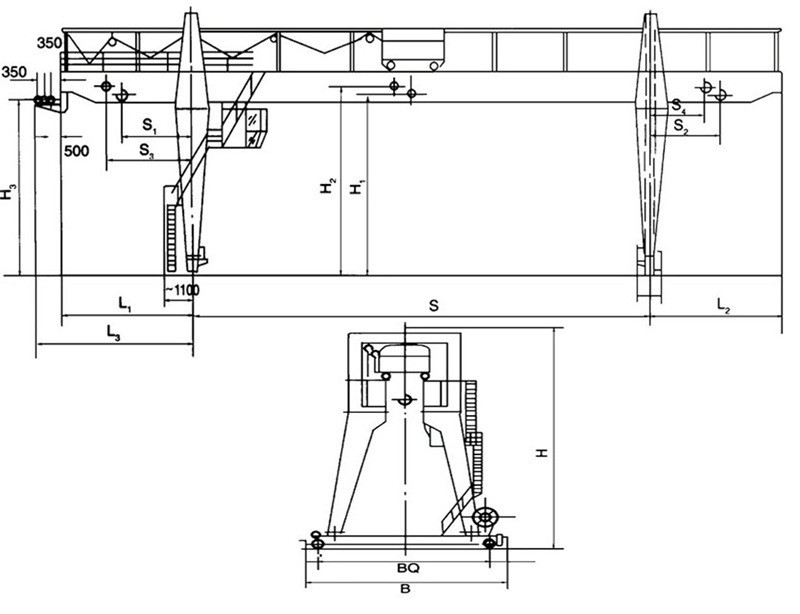

2. Structure: main beam, support legs, crane traveling organ, trolley, electric equipment, strong lifting winch

3. Power is supplied by cable or slide wire.

4. It is prohibited for lifting melt metal, flammable, explosive, corrosion, overloading, dust and other dangerous operations.

Features

The industrial gantry crane is designed to be easy to operate and maintain. It is typically equipped with safety features such as limit switches, overload protection, and emergency stop buttons.

Double Girder Gantry Crane China Environmental Conditions:

1.The temperature in the working environment should be in the scope of -20DC to 45 DC and the relative humidity is not higher than 95%(with dew).

2.During work, the wind speed should be no higher than 20m/s; and during non-work, the wind speed should be no higher than 44m/s.

3.The crane travelling lane is supposed not to slope more than 1% and no more than 3% for local slope. The ground slope on the two sides of the span should be in the same direction, that is to say, both up slope or down slope at the same time.

Specification

Lifting Capacity | T | 16/3.2 | 20/5.0 | 32/8.0 | 50/10.0 | 75/20.0 | ||

Span | M | 18-35 | ||||||

Max. Lifting Height | Main hook | M | 10/12 | |||||

Aux hook | 10.6-12.6 | 10.6-12.6 | 10.7-12.7 | 11.1-13.1 | 11.1-13.1 | |||

Working System | A5 | |||||||

Speed | Hoisting | Main | m/min | 15.3 | 15 | 13.2 | 5.9 | 6.25 |

Aux | 22 | 19 | 17 | 13.2 | 9.28 | |||

Trolley Travelling | 44.7 | 44.7 | 38.6 | 36 | 38.9 | |||

Crane Travelling | 30-35 | 34.5-32.9 | 52.53 | 45-38.6 | 38.5-32.6 | |||

Weight | Trolley | t | 7.1 | 8.1 | 11.7 | 16.8 | 29.4 | |

Total Weight | 92-142 | 105-148 | 92-142 | 111-156 | 189-245 | |||

Max. Wheel Load | 275-369 | 341-435 | 275-369 | 392-483 | 314-361 | |||

CASE

Explore Sinoko Crane's Industrial Double Girder Gantry Crane, designed for heavy-duty industrial applications. With robust construction and advanced control features, it offers superior lifting capacity, efficiency, and stability for large-scale material handling.

Installation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a QuotePakistan Scrap Steel Dumping Container Gantry Crane Project Case

The Sinoko crane, leveraging years of experience and outstanding technology, designed a container gantry crane for customers, successfully solving the problem of transporting scrap steel for them.

Learn More Get a QuoteInstallation of 3T Portable Gantry Crane for Thai Manufacturing Facility

The 3 ton portable small gantry crane specially designed by Sinokocranes for Thai customers has significantly reduced the production costs for the customers and enhanced their production efficiency.

Learn More Get a QuoteFAQs

The crane is designed for heavy-duty lifting with customizable capacities to meet diverse industrial needs.

It’s ideal for manufacturing, steel plants, and construction industries requiring heavy lifting solutions.

The crane features a robust double girder structure, ensuring enhanced stability and performance under heavy loads.

Yes, it is designed for both indoor and outdoor applications, especially in harsh environments.

The double girder design offers increased lifting capacity, greater stability, and a more efficient lifting process.

Visit the product page or contact our sales team for a detailed quote and further product information.