Overview:

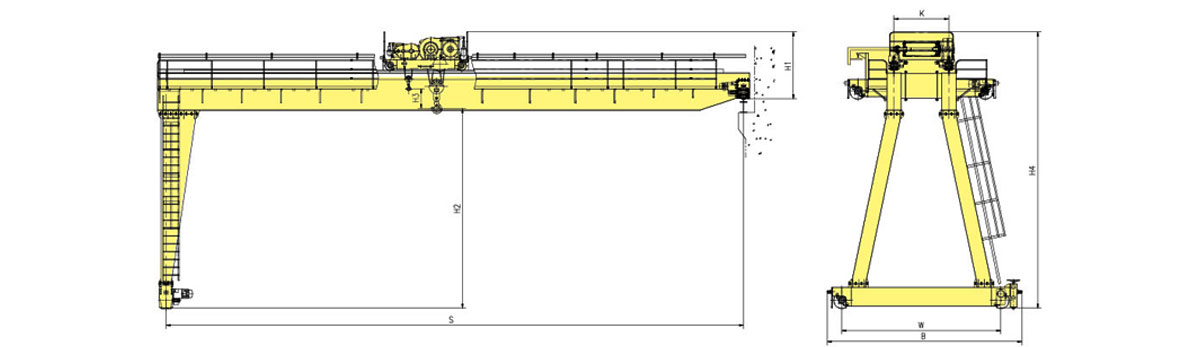

Semi-gantry cranes are a versatile and cost-effective solution for lifting and moving heavy loads in industrial settings. They combine the design of an overhead bridge crane with that of a motorized gantry crane, The crane is typically powered by a powerbar and collector assemblies along the elevated runway side of the Semi Gantry Crane and distributed by a festoon system to the hoist trolley.

Semi-gantry cranes can be controlled either by a wired pendant control or with an optional crane radio remote control system.

Semi-gantry Cranes Type

There are two types of semi-gantry crane, one is a single beam semi-gantry crane, one is a double girder semi-gantry crane, A single beam semi-gantry crane is a type of gantry crane that has one beam supported by two legs, while a double beam semi-gantry crane has two beams supported by two legs. Both types of semi-gantry crane are used to lift and move heavy loads in industrial and commercial settings.

Features

1.Overload protection.

2.Main lifting motor with thermal protection.

3.Hooks with latch.

4.Rubber buffers.

5.Protective earthing.

6.Crane switch and travel and end switch

7.Emergency switch can stop all movement when any dangerous happened.

8.Sub-assemblies characteristics are tested before assembly.

9.All cranes must be pre-assembled and tested before leaving factory and offer the certification of test.

Specification

| Lifting capacity | t | 10-50 | |

| Span | m | 18-35 | |

| Lifting height | Main Hook | m | 10,12 |

| Auxiliary Hook | m | 10.6, 12.6, 10.7,12.7,11.1,13.1 | |

| Working class | A5 | ||

| Speed | Main | m/min | 5.9-9.8 |

| Auxiliary | m/min | 9.8-17.9 | |

| Trolley travelling | m/min | 38.2-43.8 | |

| Crane travelling | m/min | 30-37.5 | |

| Motor | Main | KW | YZR160L-6/15 |

| Auxiliary | YZR160L-6/11 | ||

| Trolley travelling | YZR160L-6/15 | ||

| Crane travelling | YZR160M2-6/2X3.7 | ||

| Max Wheel Load | KN | 150-475 | |

| Steel Track Recommend | P38、P43、P50 | ||

| Power source | 380V 50HZ | ||

As a leading crane manufacturer, Sinoko semi gantry cranes are highly efficient and reliable lifting machines, designed with flexibility and customizable features. They are used in a variety of industries, including shipbuilding, automotive manufacturing, heavy machinery manufacturing, warehousing and logistics, and oil and gas. Customers have consistently praised the performance and reliability of these cranes.

CASE

Explore how the Sinoko Semi-Gantry Crane boosts productivity and reliability in your operations. Ideal for tight spaces and heavy lifting, this versatile crane offers a cost-effective solution for industries like manufacturing and logistics. Discover its real-world applications today!

40.5T Rail-Mounted Gantry Crane Installation for Port Logistics Efficiency

The RMG gantry crane designed and manufactured by Sinokocrane has effectively solved the problems for the customers and reduced their operational costs.

Learn More Get a Quote5T Portable Gantry Crane Deployment for Australian Equipment Rental

The portable gantry cranes provided by Sinoko Cranes for the leasing company of Australian customers have significantly increased the number of rentals for the customers and enhanced the revenue of their companies.

Learn More Get a QuoteInstallation of 10T European-Style Gantry Crane for Pakistani Client by Sinoko Cranes

Struggling with slow manual gates? Sinoko's European gantry crane slashed Pakistan customer's downtime by 64%! Transform your access efficiency – contact us!

Learn More Get a QuoteFAQs

A semi-gantry crane is ideal for lifting heavy loads in environments with limited space. It combines the benefits of a gantry crane with the flexibility of rail-mounted operation, commonly used in manufacturing, warehouses, and workshops.

The Sinoko semi-gantry crane offers a robust, space-saving design, high lifting capacity, and smooth operation. It is engineered to handle heavy-duty tasks with precision and reliability, suitable for both indoor and outdoor applications.

The semi-gantry design allows for efficient use of space while still providing excellent lifting capabilities. This makes it a cost-effective solution for facilities where full gantry cranes may not be feasible due to space constraints.

Yes, the semi-gantry crane can be customized based on your specific requirements, including lifting height, span, and load capacity. Our team will work with you to provide the best solution for your operational needs.

Routine maintenance includes checking the lifting mechanism, inspecting the rails and wheels, lubricating moving parts, and ensuring all electrical components are functioning properly. Sinoko provides detailed manuals and services to support your maintenance needs.

Yes, the Sinoko semi-gantry crane is designed for both indoor and outdoor use. It is built to withstand a variety of working conditions, including construction sites and ports, ensuring reliable performance across various environments.