According to the structure of the gantry crane, the main beam needs to be hoisted as a whole, which is the largest component and key factor in the installation of the portal crane.

First

The gantry cranes are generally installed in a bottom-up manner. First, the trolley and the lower beam are installed on the rails, and then the flexible legs and the rigid legs are respectively installed on both sides, and the legs are stabilized by the temporary cable wind ropes. Truss-type girders need to be assembled on the site first. They can be used as a horizontal reference for the carriage to move along the rails. When the main girder is assembled, care should be taken to maintain its upper crown at the mid-span to compensate for the sinking deflection caused by its own weight. The conventional installation method of the main girder is to lift the main girder horizontally by using a single crane or double cranes with other hoisting equipment. Before the main girder is hoisted, the center of gravity must be accurately calculated, and then the location and load of the hoisting point of the auxiliary crane should be determined accordingly. When the two cranes are hoisted, the load should be reasonably distributed according to the lifting performance of the auxiliary crane. The lifting load of each auxiliary crane must not exceed 80% of its allowable load. According to the condition of 40t/40m gantry crane main girder, choose 2 cranes or crawler cranes with a lifting capacity of 50t to lift and meet the lifting requirements. When using a single crane, it is necessary to choose a crane with a weight of 100t, which has a large tonnage and is not economical.

The weight of the main beam is relatively large. Under normal circumstances, the lifting mechanism, lifting trolley and driver's cab and other components are installed after the main beam is installed.

Second :Main beam separate lifting installation method

In the case where the auxiliary crane configuration on the construction site is not large enough, the main girder can be installed separately by tilting and lifting. This method is rare in the installation project, the method is novel, and the requirements for the selection of the auxiliary crane are low and relatively economical.

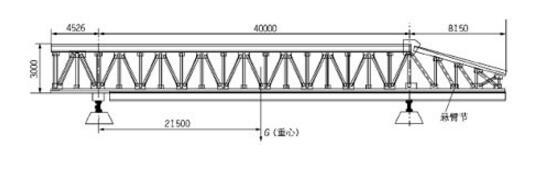

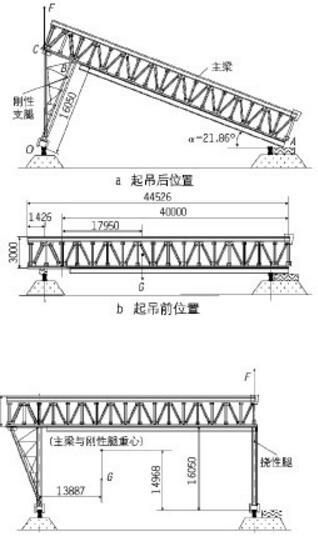

The 40t/40m gantry crane main crane separate crane installation method is as follows: first in the ground assembly of the main beam, due to the need for unilateral lifting, the main beam flexible leg side cantilever section is not installed, this time the main beam length is 44.526m, The total weight of 5 knots is 42.792t. Use an auxiliary crane to lift the A-side of the flexible leg of the main beam as the fulcrum, lift the C-side main beam of the rigid leg, and use another small auxiliary crane or chain block to move the assembled rigid leg under the main beam. The rigid leg is connected to the main girder when it is tilted (see Figure 2a); then the auxiliary crane lifts the flexible leg end of the main girder and the assembled flexible leg is moved to the main girder with another small crane or chain block Under the connection installation; finally install the main beam boom section and other parts.

In order to ensure that the main beam is lifted unilaterally, it can be accurately connected with the rigid legs supported on one side of the track. It is necessary to calculate the position of the main beam across the track in advance. According to the relevant dimensions shown in Fig. 2, it can be calculated that OA = 43.10m. When the main beam is not placed on the track before being lifted, the end of its rigid leg side should exceed the track by 44.526-43.1 = 1.426m ( See Figure 2b).

The lifting load F of the auxiliary crane can also be calculated from the relevant parameters shown in Figure 2a. When the main beam is lifted from the horizontal position, Fmax = 212.9 kN; when the main beam is connected with the rigid leg, Fmin = 206.1 kN.

The main beam flexible leg end lifting diagram is shown in Figure 3. After calculation, when the main beam inclination angle a changes from 21.86° to 0°, the lifting force changes from 235.16-190.6kN.

From the above analysis, it can be concluded that the installation of the main girder can use only one auxiliary crane with a capacity of 50 tons.

Third:Technical and Economic Comparison

(1) The conventional main girder hoisting method, the maximum load of the auxiliary crane is the weight of the main girder, up to 42.79t, at least 100t class cranes must be installed; using separate hoisting methods, the load of the auxiliary crane is greatly reduced, and the maximum lifting load is only 23.5t, with a 50t-class crane, can meet the needs of the general site, effectively reducing installation costs.

(2) The conventional main beam lifting method requires the rigid and flexible legs to be installed to lift the main girder. Both legs must pull the cable wind rope, which is not conducive to the on-site operation; instead, separate lifting and lifting methods are used to lift the main girder. The cable wind rope on one side leg has lower requirement on the installation site and is more conducive to operation. After the rigid leg is connected with the main beam, a stable state is formed and it is easier to ensure safety.

(3) In the conventional main girder hoisting method, both legs must be installed and installed at the same time when hoisting. There are many high-altitude workers and they must be continuously operated to increase the safety risk. In the case of split lifting, the two legs can be divided. Combinations and installations require less site requirements and can be installed in relatively small spaces, while reducing the time for continuous operations and reducing safety risks.

(4) Compared with the conventional lifting method, the separate lifting and lifting methods, although the rigid legs and the main beam are inclined for a time, the installation process is more complicated and more difficult, but only one auxiliary crane with a lifting capacity of 50t is needed, as long as the Take corresponding measures during the installation process, this method is still feasible.

(5) The main control method of the main beam lifting method is the lifting of one side of the rigid leg, which is mainly when the main beam is assembled on the ground. It must be accurate to ensure that the main beam lifting can accurately position with the rigid leg.

The installation of gantry crane requires experience and attention to detail to prevent potentially dangerous safety issues. Sinokocranes offers unparalleled experience and expertise in erection and start-up installation of the following:

Cranes

Electrification Systems

Runways

At Sinokocranes, we provide our customers with the best turn-key crane systems. We offer complete installation, load testing and start-up services on every crane we sell.

If you’re looking to partner with an experienced and reliable gantry crane manufacturer, or want to schedule a consultation, give us a call today. We offer free quotes and consultations on every project!