Overview

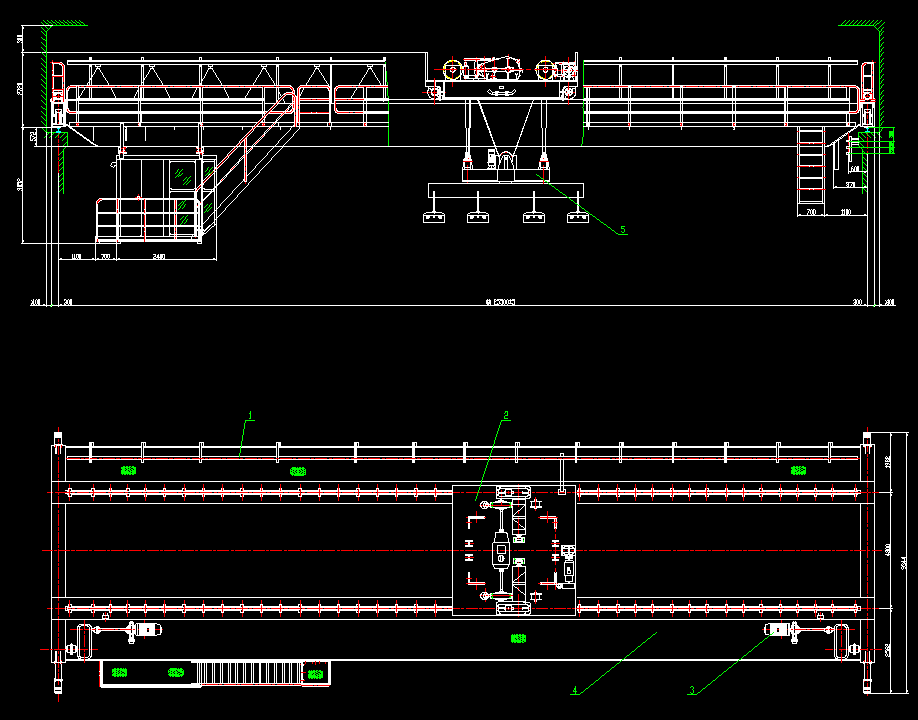

QL Double Beam Electromagnetic Bridge Crane with carrier beam mainly consists of bridge, crane traveling mechanism, trolley, long carier beam, electric equipment and electromagnetic chuck.

When used, the rotary part of the hanger of electromagnetic disk must be locked up with screws and no rotation is allowed.

The crane mainly relies on the magnet carrier beam, using the electromagnetic principles, then through electricity and magnetic plate to suck the goods firmly hanging to the designated place.

Cut the electricity, steel and irons will be lay down.

It is the most convenient crane to transfer the long pcs sheet metal, steel billet, ignots and rolling mill deform bar etc.

Features

Rugged-all-welded construction with good moisture-proof

Optimized design by computer with reasonable structure, high suction weight ratio and low energy consumption.

Energizing coils processed by special technology with improved electrical and mechanical performance; heat-resistance grade of insulation material grade C with long using life.

High temperature type electromagnet adopting unique method of heat-protection. Temperature limit of the attached items is increased from 600~700 degree, which expands application range of lift electromagnet.

Easy and convenient installation, operation and maintaince

It is special magnetic pole is suitable for round coil with different diameters; selection of electromagnet depends on the length of round coil. If the electromagnet is long enough at a time

Specification

Additional features may include adjustable hooks and special attachments to customize the crane for the particular application. If you want to learn more about overhead crane with electromagnetic beam, please contact us.

CASE

Explore how our electromagnetic bridge cranes are applied in real-world projects. From heavy steel plate handling to high-temperature lifting, our case studies show how we deliver tailored, efficient solutions for complex industrial needs. Discover more crane applications and success stories.

32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote3× 5T European-Style Single-Girder Cranes for Kenyan Sugar Refinery

Sinoko cranes has designed three 5-ton bridge cranes for Kenyan customers, which have solved their problems. Come and contact Sinoko cranes to solve your lifting problems.

Learn More Get a QuoteFAQs

This QL double-beam overhead crane with an electromagnetic carrier beam excels at lifting and transferring heavy steel items such as ingots, continuous casting plates, thick steel sheets, billets, and rolled deformed bars—making it ideal for factories, shipyards, and industrial production lines.

The crane uses a magnet carrier beam powered by electromagnetic principles to securely pick up steel and iron. To release the load, power is switched off. The rotary part of the hanger must be locked with screws to prevent unintended rotation.

Built with a rugged, fully welded structure that resists moisture, the crane is optimized through computer-aided design for high suction efficiency, low energy use, and long coil lifespan. Its electromagnet is heat resistant (insulation class C), enabling safe lifting even at temperatures up to 600–700 °C.

The magnetic pole design is specially engineered to lift various round coils of different diameters. Customers can choose the appropriate electromagnet length based on the material size, allowing effective handling in a single lift.

Its primary structure includes a double-beam bridge, a crane traveling mechanism, a trolley, a long carrier beam, electrical systems, and the electromagnetic chuck—together offering robust and precise material handling.

Designed for easy setup and maintenance, this crane ensures operator convenience and minimal downtime, backed by its intuitive structure and electromagnetic system.