Do you still think that small workshops or cluttered workshops can only rely on manual production and work? If so, you may want to consider a jib craneA jib crane is a crane that has a combination of a column and a cantilever with a simple design. Since the column is fixed on the ground or on the wall, it is usually suitable for smaller work cell areas for heavy, repetitive lifting tasksBelow we will introduce the jib crane in detail from three aspects: design, type, and components.

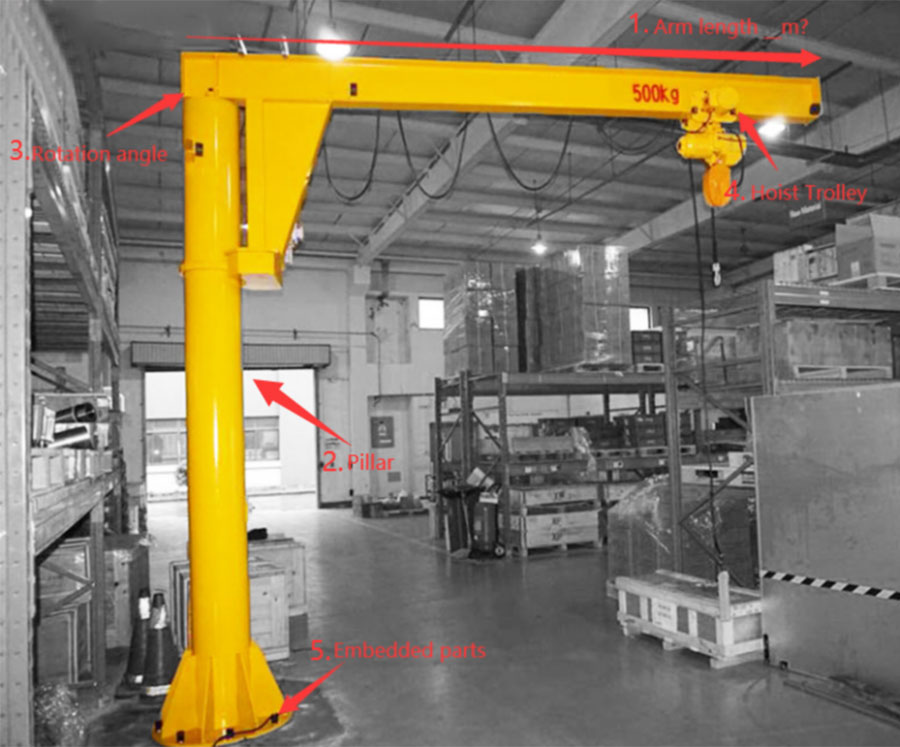

1. Boom length: the main beam of the trolley traveling back and forth, this data usually determines the working range of the jib crane. Sometimes, in order to combine the actual working conditions, it can also be designed as a knuckle boom crane

2. Uprights/pillars: Vertical beams used to support booms on freestanding and mast systems.

3. Rotation angle: 180°, 270° and 360°. There are manual and electric rotation modes

4. Hoist trolley: It can be equipped with chain hoist or wire rope hoist, and the lifting and running of the hoist can be customized as manual or electric. If it is electric, we will also configure the electric control cabinet and remote control

5. Embedded parts: used for the fixation of pillars and ground, usually reinforced disc construction concrete

Below we will discuss the different types of jib crane systems available and provide the functional range, advantages and disadvantages of each system.

This is the most common type of cantilever system because they can be installed almost anywhere, indoors or out. An open area that supports a single unit of work. They can be used outdoors on docks or loading docks, or indoors for machining and assembly operations, where multiple booms can be combined for staged operations.

Basic parameters:

Load: Below 7T

Column: ≤10m

Arm length: ≤10m

Can be rotated 360°

Advantages: heavy load, longest span, 360° rotation.

Disadvantages: high production cost, large transportation volume, high cost.

Components: column, beam, electrical system, lifting mechanism, rotating mechanism, embedded parts.

Jib cranes without columns are flat-mounted and bolted to reinforced concrete or indoor columns for indoor use. These types of jib crane systems do not require special poured foundations,

Because no special foundation is required, these wall cranes can be installed faster,

Basic parameters:

Load: below 2T

Arm length: ≤7m

It can only be rotated 180° when installed on the wall, and can be rotated 270° when installed on a column

Pros: Easy installation, portability

Disadvantages: small load, small arm length.

Components: beam, electrical system, lifting mechanism, swivel mechanism, mounting plate and bolts.

A crane that can run on the workshop wall requires 3 separate rail and is complicated to install.

Basic parameters:

Load: below 2T.

Arm length: ≤7m.

not rotatable.

Benefit: Can run back and forth throughout the workshop.

Disadvantages: complex installation, high cost.

Components: beam, electrical system, hoisting mechanism, rail.