Your are here: Home > Products > Overhead Crane > Monorail Crane

Monorail Crane also called single beam crane or single girder crane, It is a kind of light duty cranes popular using for workshop, warehouse, maintenance, material transfering etc.

Working temperature: -25°C ~ +40°C.

Lifting capacity: 0.25-20ton

Span length: 7.5-32mtrs

Lifting height: 6-30mtrs

Working duty: Class A3- A5

Power: AC 3Ph 380V 50Hz or according to client's requirement

Control mode: Cabin control/remote control/control panel with pendant line

The Monorail Crane is a cutting-edge lifting solution that offers exceptional efficiency, versatility, and safety for various industries. This innovative crane system is designed to streamline material handling processes, providing a cost-effective and reliable solution for transporting heavy loads in a wide range of environments. With its unique design and advanced features, the Monorail Crane stands out as a top choice for businesses seeking to enhance their lifting operations.

● Main beam structure of monorail crane

● End beam structure of monorail crane

● Electrical section of monorail crane

●Hook of monorail crane

●Other of monorail crane

Lower upfront costs due to less material and faster installation.

The most economical choice for light to medium duty cranes.

Weight overload protective device

Top quality polyurethane buffer

Crane traveling limit switch and lifting limit switch

Low voltage protection function

Emergency stop system

Laser anti-collision system

The standardized design of Sinoko electric monorail crane can optimize the use of facility space. The configuration of single-girder cranes is standardized and can be combined with our hoist series to achieve maximum space utilization. In addition, single-girder cranes are also lighter in weight.

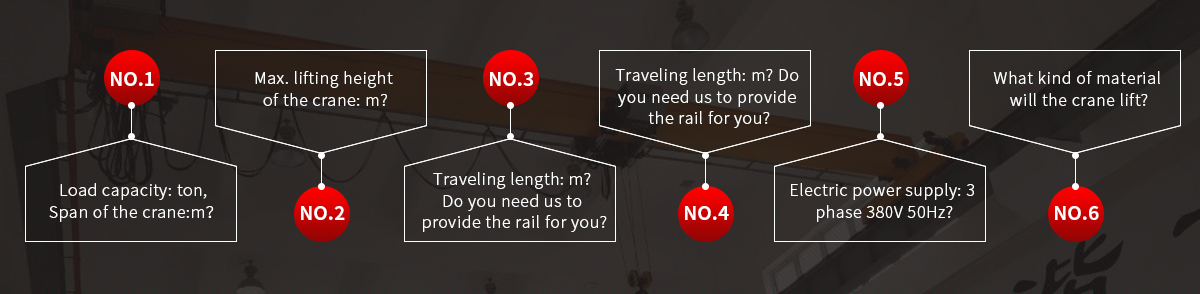

In order to provide a suitable overhead crane system for your plant, please inform us of your specific requirements, including but not limited to:

| Lifting capacity(T) | 1,2,3,5,10T | 16,20T | |||||

| Span(M) | 7.5-31.5M | ||||||

| Crane travelling mechanism | Travelling speed(m/min) | 20/30 | 20/30 | ||||

| Motor | Model | ZDY21-4 | ZDY21-4 | ZDY122-4 | ZDY131S-4 | ZDY112L1-4 | |

| Power(kw) | 2/0.8 | 2/1.5 | 1.5/2 | 2.2/2 | 2.2/2 | ||

| Rotation (m/min) | 1380 | 1380 | |||||

| Lifting mechanism | Electric hoist model | CD1/MD1 | MD1/HC | ||||

| Electric hoist travelling mechanism | Lifting speed (m/min) | 8,8/0.8 7,7/0.7 | 3.5 3.5/0.35 | ||||

| Lifting height (m) | 6 ,9 ,12, 18, 24, 30 | 12,18,24,30 | |||||

| Travelling speed (m/min) | 20(30) | 20(30) | |||||

| Motor | Taper Squirrel-cage type | Taper Squirrel-cage type | |||||

| Work duty | A3-A5 | ||||||

| Power supply | 380V 50HZ three phase | ||||||

| Wheel diameter | 270mm | 370mm | |||||

| Tread of trail | 37-70mm | 37-70mm | |||||