Your are here: Home > Products > Overhead Crane > Thermal Power Plant Overhead Cranes

Sinokocranes conducts detailed management of on-site lifting operations to study the rationality of construction plans. This will reduce the cost of using large cranes, which directly affects the size of the power plant profits.

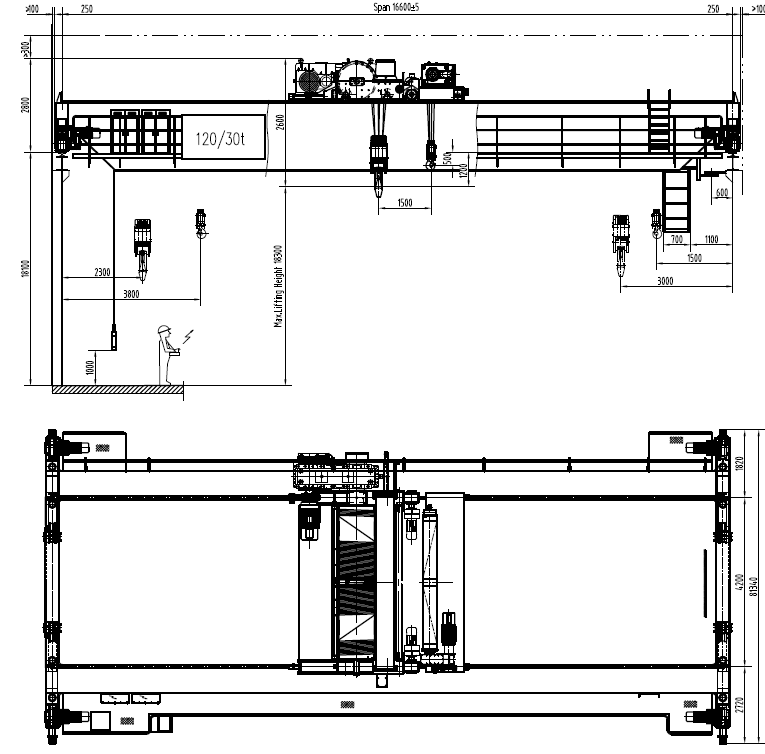

The power plant bridge crane is used for hoisting and assembling the power plant stator, steam turbine stator and rotor, The overhead crane is required to be heavy in weight and low in frequency of use. In order to save costs, two double girder bridge cranes can be selected for the hoisting and assembly of the rotor. Sinokocranes has a successful project case and is well received by customers;

Power plant overhead cranes are usually installed in the main engine plant of power plants for the installation and maintenance of generator sets, and the lifting and handling of electrical equipment and other items. The European double-girder crane is usually selected for the main engine plant of the power plant, which has the advantages of small clearance, compact structure, safety and reliability, and firm use.

The scale of operation of thermal power plants is generally relatively large, and the extensive application of cranes in the remanufacturing process has greatly improved the production efficiency. However, the safety of the crane and the safety incidents it brings cannot be ignored.

1. Save working space: Smaller left and right space restrictions, increase working space. The space above the track/track is small, and the workshop space can be fully utilized.

2. Low cost of service and maintenance: reliable performance, durable, reduce extra cost. High quality and performance components require less maintenance and repairs. Lower energy consumption.

3. High performance: The frequency conversion technology is adopted to reduce the working load and make the crane run at high speed under light load. The speed range of 1:10 ensures that the crane runs smoothly and reduces the impact on the workshop. Adopt anti-shake technology to achieve precise positioning.

(f) Trolley rail: QU100; Crane Wheel: Qu120;

(g) Wheel pressure: trolley 530kn; Crane 300kn;