Your are here: Home > Products > Electric Hoist > Wire Rope Hoist > FEM Standard A5 Working Duty Electric Wire Rope Hoist

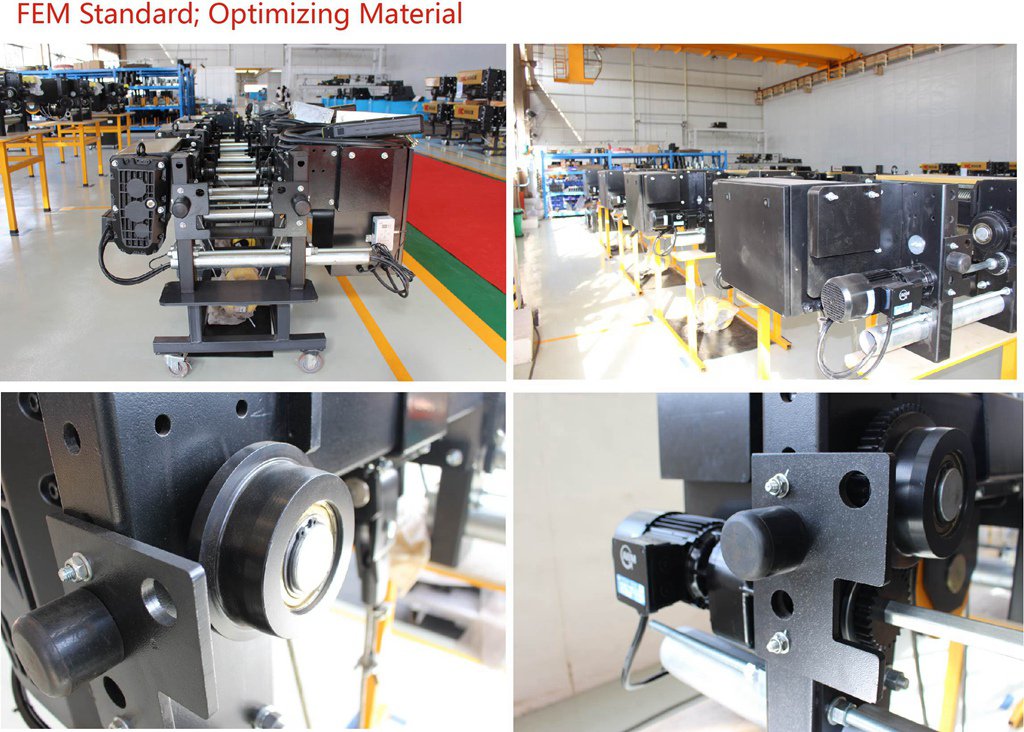

Working Duty: FEM2M; FEM3M (ISOM5; ISOM6)

Sinokocranes Follow the most advanced technology of electric hoist design. Make innovation for hoist inteligent functions, high safey by monitoring system.

We have supplied the high quality electric hoist of FEM Standard for many advanced users.

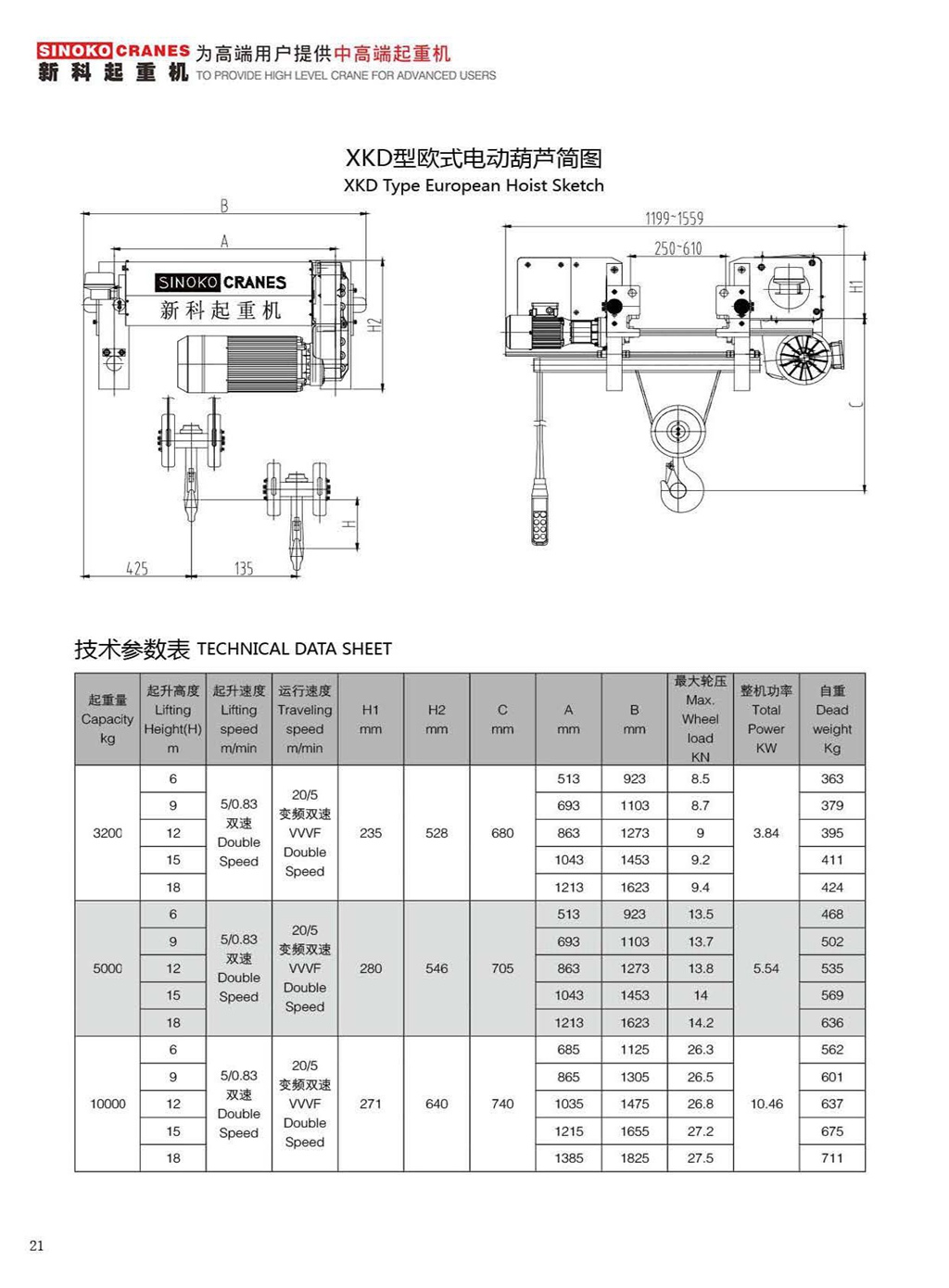

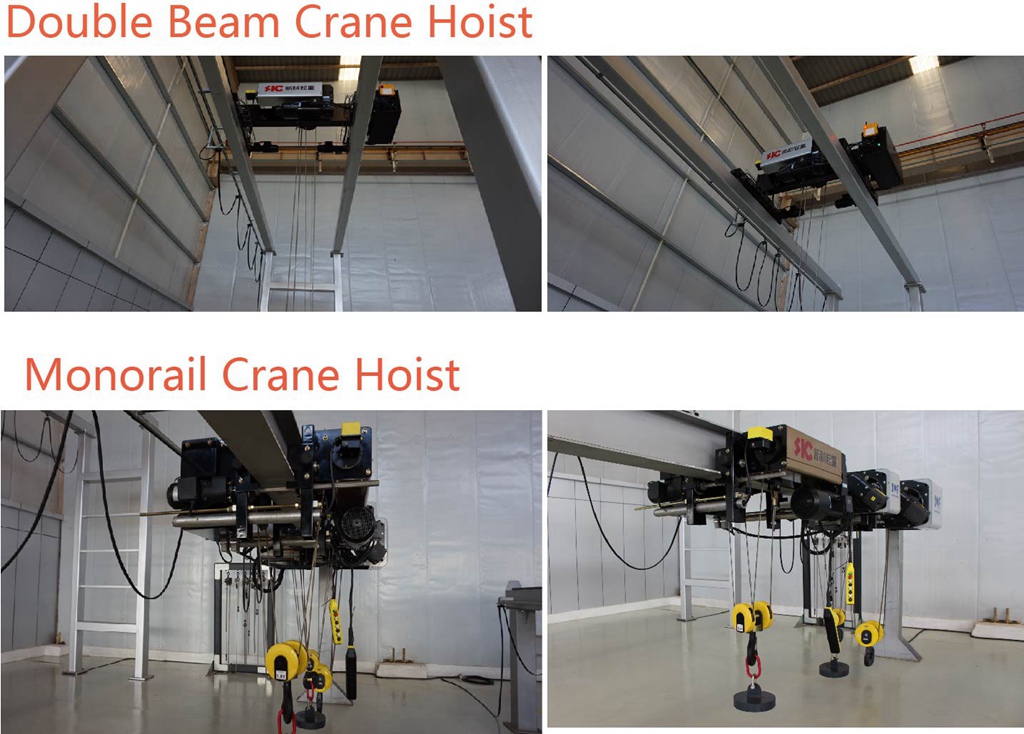

The frontier techniques and component performance of the European electric hoist ensure the product size and equipment height. The compact structure is ensured under the premise of ensuring performance. In the same workshop and work area, the European electric hoist can cover a larger operation scale and increase the internal area of the factory. Application rate, reduce dead zone. If the design is based on the parameters of the finished product during the design stage of the plant, the request for the height of the plant and the bearing capacity of the lifting equipment can be greatly reduced, so that the customer can reduce investment in the plant by more than 10% and promote investment efficiency.

1. Working level: FEM2M; FEM3M (ISOM5; ISOM6)

2. Three-stage transmission, involute helical gears, oil bath cast aluminum gearbox system. The precision gear set works in leak-proof cast aluminum gearboxes. The housing of the gear box is designed to be easily cooled by air and is easy to repair when a fault occurs. Provides low headroom design specifications while ensuring maximum lift height. Save your costs and improve efficiency. The hoist motor is a two-speed adjustment type, which can increase the vulgar ratio to 6:1. It can meet the requirements of positioning, high-speed operation, and quick takeoff and landing.

3. The rope groove adopts deep groove design and standard high-strength wire rope guiding mechanism to ensure that the rope is tighter and more regular.

Ensure lifting safety while extending the life of the wire rope.

4. High-strength DC disc brakes can achieve up to 2 times the nominal torque, enabling fast, active braking and holding

5. Traction wheels made of alloy steel can be used on wide rails or even on curved rails. Drive wheels on both sides of the main engine provide more active drive guidance.

6. All electrical control components use a safe IP54 protection level and you can easily access the parts you need to see when needed.

7. High-strength metal structure is safe and reliable, to ensure the stable operation of the host.

8. The trolley mechanism can be easily adjusted to adapt to different track widths.

9. In the upgrade of high-end range, it is possible to arbitrarily set the upper limit position to meet the most extensive use requirements.